Timeline

2021 – 2026 Mill Operations Timeline

Prior to 2020, the New-Indy Catawba mill produced mostly white paper, which was used by customers to print magazines, catalogs and similar materials. In 2020, New-Indy converted portions of the mill to manufacture unbleached containerboard, which is used by customers to produce various packaging products. The mill conversion led to now-resolved odor and contamination issues inherited from the mill’s previous owners, highlighting that the mill has made over $85 million in upgrades, including a new steam stripper, wastewater lagoon improvements and air quality monitoring to ensure compliance with all regulations.

2021

Week of: March 1

Mar

- Full mill odor survey conducted by external consultant

Mar

Week of: March 8

Week of: May 3

May

- Brought foul condensate steam stripper back into service

- Optimized calcium nitrate supplementation (split feed)

- Enhanced surface solids removal in ASB

May

Week of: May 10

Week of: May 24

May

- Installed on-site fence line H2S monitors in accordance with EPA regulations

- Activated company landing page

Jun

Week of: June 7

Week of: June 14

Jun

- Continued surface solids removal from ASB

- Added ferric chloride to Holding Pond 1 influent ditch

- Initiated hydrogen peroxide addition to Holding Pond 1

Week of: June 28

Jun

- Continued surface solids removal and aerator repairs

Jul

Weeks of: July 12 & July 19

Week of: September 13

Sep

- Initiated the use of a second dredge unit on the ASB to continue the removal of sub-surface solids

Week of: October 25

Oct

- Initiated operation of a hydrogen peroxide diffuser running the length of #1 Holding Pond

- NALCO Odortech system installed (Naturally reduces hydrogen sulfide and associated odors).

Dec

Week of: December 13

2022

- Initiated oxygen addition to the primary clarifier.

Mar

Week of: March 27

Week of: April 11

Apr

- Initiated ferric chloride addition to the primary clarifier underflow.

- Began operating a turbulator in the ASB, which pulls oxygen from above the water surface down a steel chute to oxygenate below the surface of water. This not only allows the dredging equipment to be primarily used in the south end of the ASB but serves the same purpose of adding oxygen to the water.

Jun

Week of: June 20

Week of: June 27

Jun

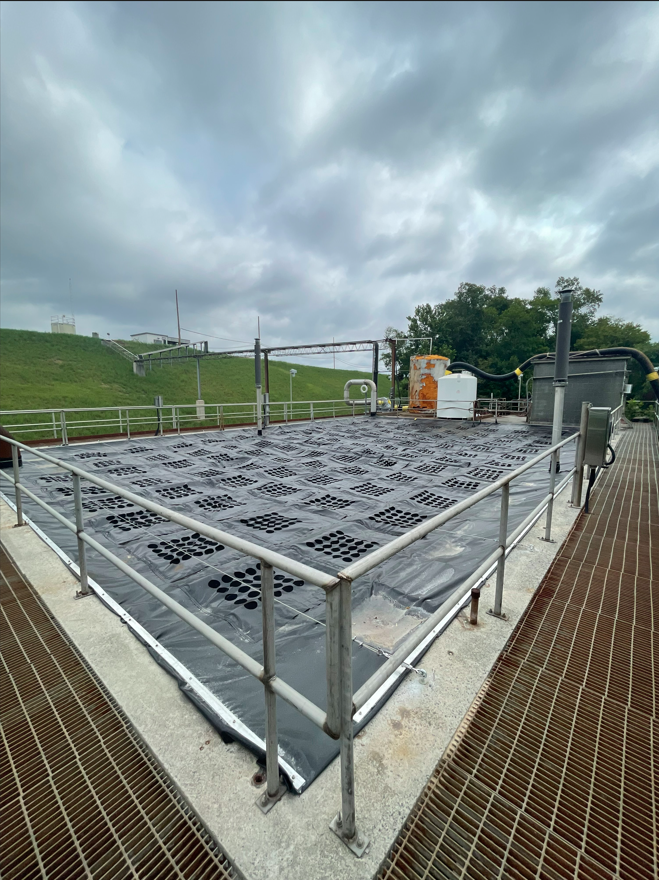

- Installed permanent PAB cover and filter system, which operates aerators continuously to ensure an adequate level of dissolved oxygen is present before effluent reaches the Catawba River.

2023

- Design of new steam stripper complete and application for permit submitted to SC DHEC.

Mar

Week of: MARCH 27

Week of: June 12

Jun

- Removal of legacy solids from the EQ Basin complete.

-

New-Indy completed the installation of a massive spill containment system that captures and refines excess used chemicals and recycles them back into the system rather than becoming waste.

Oct

Week of: October 23

2024

Week of: July 22

JUL

- The South Carolina Department of Environmental Services Bureau of Air Quality approved Air Quality Construction Permits for New-Indy Catawba to move forward with the construction of an additional foul condensate steam stripper.

2025

- New-Indy commences operation of the new foul condensate steam stripper, an innovative system designed to enhance production and promote cleaner, more sustainable operations.

Apr

Week of: April 14

Abbreviation Key

| Abbreviation | Meaning | Functional Description |

|---|---|---|

| ASB | Aeration Stabilization Basin | Biological stabilization of wastewater organics |

| CEG | Community Engagement Group | Build trust and confidence with local citizens and other stakeholders and establish an effective and regular dialogue with the local community |

| EPA | Environmental Protection Agency | US environmental agency |

| EQ Basin | Equalization Stabilization Basin | Used as a means of buffering or equalizing the characteristics of wastewater prior to entering the wastewater treatment system |

| H2S | Hydrogen Sulfide | Chemical targeted for ambient air monitoring |

| PAB | Post Aeration Basin | Final aeration polishing basin prior to discharge to Catawba River |

| PM3 | Paper Machine 3 | Production equipment where linerboard is made from pulp slurry |

| SCDHEC | South Carolina Department of Health & Environmental Control | South Carolina state environmental agency |