Daily Air Emissions Report

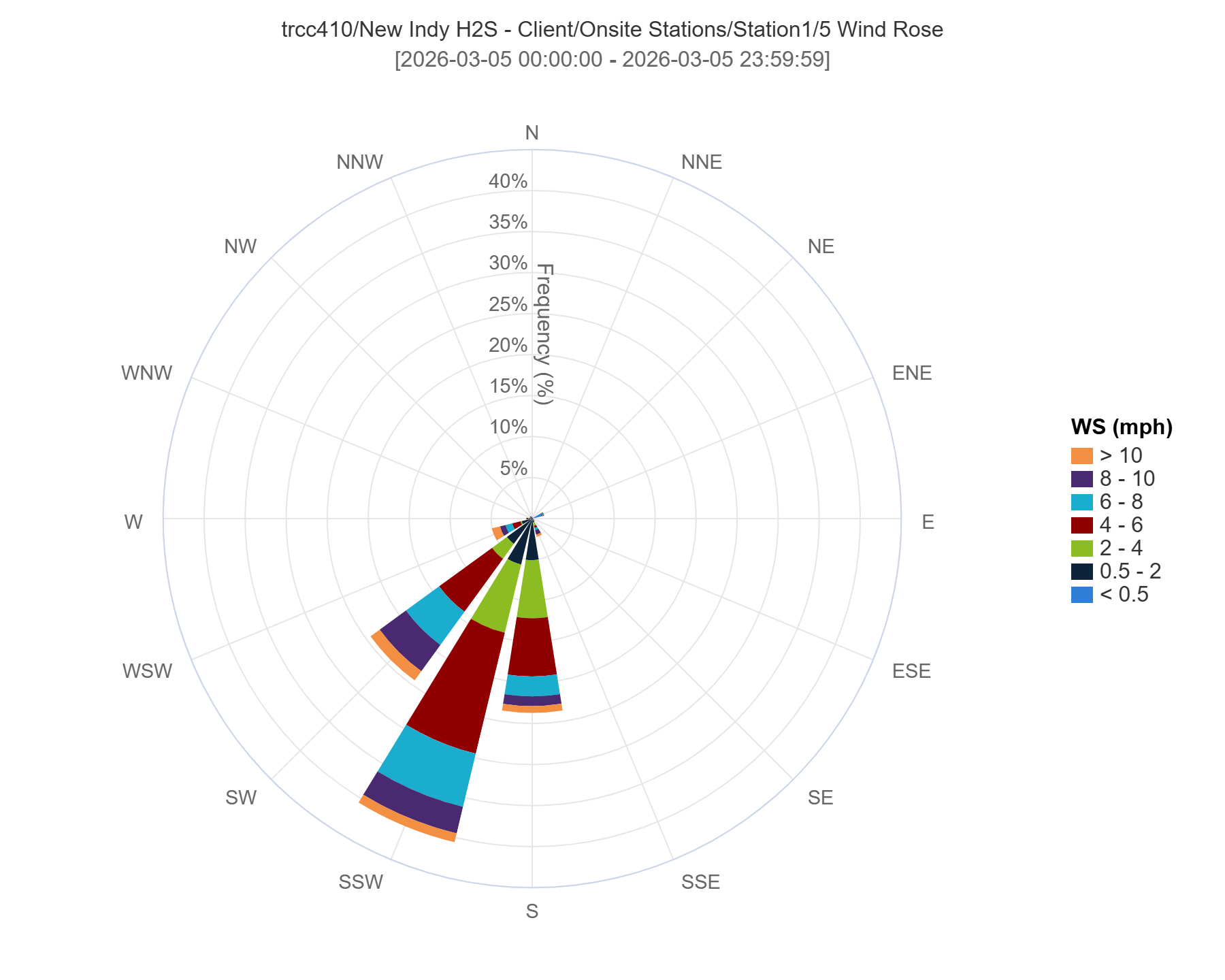

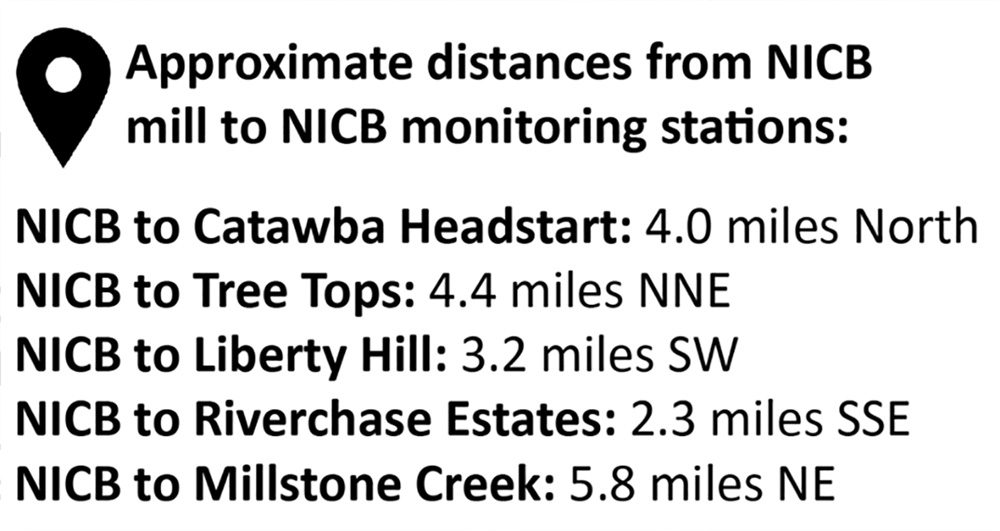

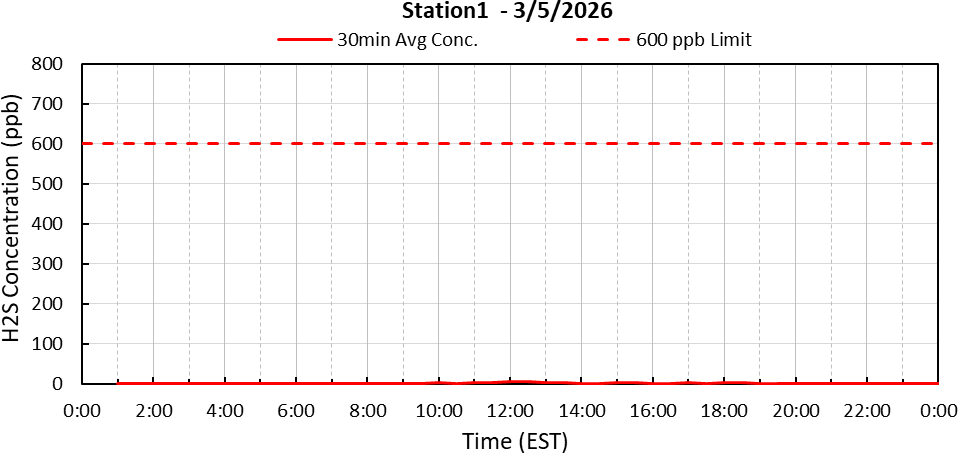

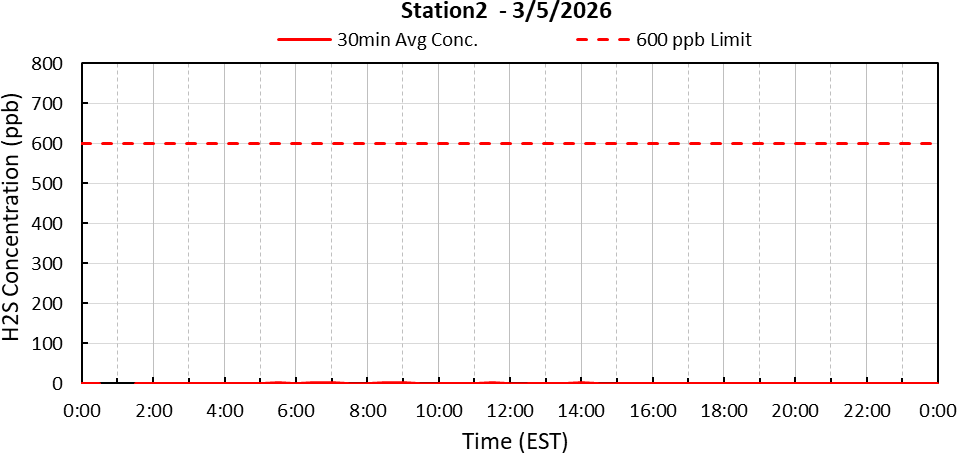

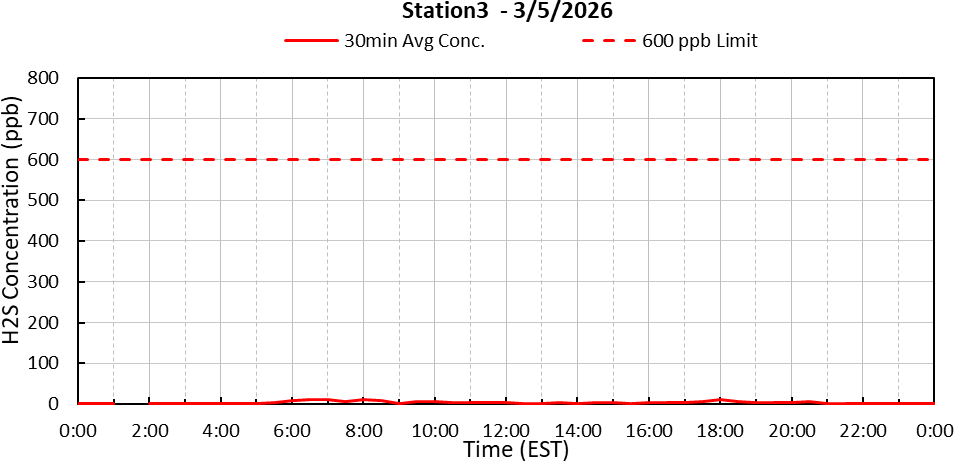

New-Indy continuously monitors hydrogen sulfide levels at the Catawba Mill. The report below shows hydrogen sulfide levels as reported by New-Indy and is updated daily.

Download Daily Reports

March 2026 Reports

New-Indy Catawba Steam Stripper Efficiency

Public Notifications

New-Indy will notify the public about operational activity that may result in changes in emissions from the Catawba Mill. Any such notices will be posted in this section.

2025 Notifications

- 2025-11-18 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2025-11-18 - New-Indy Catawba LLC - Public Notification of Downtime Activity - PENDING

- 2025-06-30 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2025-06-14 - New-Indy Catawba LLC - Public Notification of Downtime Activity - PENDING

- 2025-04-11 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2025-04-09 - New-Indy Catawba LLC - Public Notification of Downtime Activity - PENDING

- 2025-03-27 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2025-03-27 - New-Indy Catawba LLC - Public Notification of Downtime Activity - PENDING

- 2025-02-10 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2025-02-08 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2025-02-07 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2025-02-02 - New-Indy Catawba LLC - Public Notification of Downtime Activity - PENDING

- 2025-01-21 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

2024 Notifications

- 2024-12-06 New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2024-11-08 New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2024-11-01 New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2024-09-26-New-Indy Catawba LLC - Public Notification of Planned Activity - Offsite Monitor Removal

- 2024-08-29-New-Indy Catawba LLC - Public Notification of Downtime Activity-COMPLETE

- 2024-08-21 New-Indy Catawba LLC – Public Notification of Downtime Activity – PENDING

- 2024-06-29 – New-Indy Catawba LLC – Public Notification of Downtime

- 2024-06-26 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2024-05-17 - New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2024-05-15 - New-Indy Catawba LLC - Public Notification of Downtime Activity - PENDING

- 2024-05-07 New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2024-05-06 New-Indy Catawba LLC - Public Notification of Downtime Activity - Complete

- New-Indy Catawba LLC - Public Notification of Downtime Activity - ONGOING-2024-0413

- New-Indy Catawba LLC – Public Notification of Downtime Activity - COMPLETE - 2024-0412

- 2024-03-15 New-Indy Catawba LLC - Public Notification of Downtime Activity - COMPLETE

- 2024-01-18 New-Indy Catawba LLC - Public Notification of Downtime Activity - Complete

- 2024-01-05 New-Indy Catawba LLC - Public Notification of Downtime Activity - Complete

- 2024-01-02 New-Indy Catawba LLC - Public Notification of Downtime Activity - Ongoing

2023 Notifications

- Public Notification of Downtime Activity: Complete – November 09, 2023

- Public Notification of Downtime Activity: Complete – October 23, 2023

- Public Notification of Downtime Activity: Complete – October 18, 2023

- Public Notification of Downtime Activity: Complete – October 13, 2023

- Public Notification of Downtime Activity: Complete – October 9, 2023

- Public Notification of Downtime Activity: Complete – October 2, 2023

- Public Notification of Downtime Activity: Complete – September 14, 2023

- Public Notification of Downtime Activity: Complete – August 30, 2023

- Public Notification of Downtime Activity: Complete – August 25, 2023

- Public Notification of Downtime Activity: Complete – August 22, 2023

- Public Notification of Downtime Activity: Complete – July 16, 2023

- Public Notification of Downtime Activity: Complete – July 12, 2023

- Public Notification of Downtime Activity: Complete – July 4, 2023

- Public Notification of Downtime Activity: Complete – June 28, 2023

- Public Notification of Downtime Activity: Complete – June 24, 2023

- Public Notification of Downtime Activity: Complete – June 20, 2023

- Public Notification of Downtime Activity: Complete – June 18, 2023

- Public Notification of Downtime Activity: Ongoing – June 15, 2023

- Public Notification of Downtime Activity: Ongoing – June 14, 2023

- Public Notification of Downtime Activity: Complete – June 3, 2023

- Public Notification of Downtime Activity: Complete – June 07, 2023

- Public Notification of Downtime Activity: Complete – June 04, 2023

- Public Notification of Downtime Activity: Complete – June 01, 2023

- Public Notification of Downtime Activity: Complete – May 28, 2023

- Public Notification of Downtime Activity: Complete – May 11, 2023

- Public Notification of Downtime Activity: Complete – May 10, 2023

- Public Notification of Unplanned Activity: Complete – May 7, 2023

- Public Notification of Downtime Activity: Complete – May 6, 2023

- Public Notification of Downtime Activity Reset – April 28, 2023

- Public Notification of Downtime Activity – April 19, 2023

- Public Notification of Downtime Activity: COMPLETE – February 3, 2023

- Public Notification of Downtime Activity – January 25, 2023

2022 Notifications

- Public Notification of Unplanned Activity November 17, 2022

- Updated Public Notification of Planned Work October 28, 2022

- Public Notification of Unplanned Activity October 21, 2022

- Updated Public Notification of Planned Activity October 11, 2022

- Public Notification of Unplanned Activity on October 12, 2022 – Update Posted October 14, 2022

- Public Notification of Unplanned Activity on October 12, 2022

- Public Notification of Unplanned Activity on July 12, 2022 – Update Posted July 14, 2022

- Public Notification of Unplanned Activity July 12, 2022

- Public Notification of Unplanned Activity June 27, 2022

- Public Notification of Unplanned Activity June 21, 2022

- Public Notification of Planned Activity on May 11, 2022 – Update Posted on May 13, 2022

- Public Notification of Planned Activity on August 16, 2021 – Update Posted on January 28, 2022

- Public Notification of Planned Activity on January 21, 2022 – Update Posted on January 28, 2022

- Public Notification of Planned Activity on January 21, 2022

- Public Notification of Planned Activity on January 7, 2022

2021 Notifications

- Public Notification of Planned Activity on September 23, 2021

- Public Notification of Planned Activity on September 17, 2021

- Public Notification of Planned Activity on September 16, 2021

- Public Notification of Planned Activity on August 16, 2021

- Status on SCDHEC Order – 6/18/21

- Public Notification of Planned Activity on June 18, 2021

- Public Notification of Planned Activity on June 9, 2021

- Public Notification of Planned Activity on June 8, 2021

New-Indy News

New-Indy Catawba News & Announcements

New-Indy Catawba 2025 Q4 Newsletter can be downloaded here…. 2025 Q4 Newsletter... New-Indy Catawba 2025 Q3 Newsletter can be downloaded here…. 2025 Q3 Newsletter... Innovative system makes the mill one of the most efficient and environmentally friendly in the industry Click Here for Press Release...New-Indy Catawba 2025 Q4 Newsletter

New-Indy Catawba 2025 Q3 Newsletter

New-Indy Unveils New Steam Stripper

2021 – 2026 Mill Operations Timeline

Prior to 2020, the Catawba Mill produced mostly white paper, which was used by customers to print magazines, catalogs and similar materials. New-Indy converted the mill to manufacture unbleached containerboard, which is used by customers to produce various packaging products. Following the conversion, the mill experienced upset conditions that required remediation efforts and operational improvements. The timeline below outlines New-Indy’s operational updates since 2021.